Brakes

- Brakes are one of the many control systems integrated into to vehicle to control & regulate

- It regulates the speed

- They use frictional force to reduce the speed of the car

- Wheels are supplied with rotational energy by the motor/engine, when brakes are applied, this rotational energy is converted into heat energy on application of friction force

Classification based on Actuation Methods

Depending on the working medium used to actuate/ engage the brakes, they can be classified as follows

1. Mechanical

- They use mechanical linkages to transmit user input (force) to brakes

- Ex. Cables, links, levers, etc.

- Commonly found in light vehicles

- The ratio of force being provided by the user and the force being transmitted to the brakes is very low, a larger force multiplication is not possible due to space & packaging constraints

2. Hydraulic

- They are able to provide a higher degree of force multiplication

- Found in Light & Medium sized vehicles and higher displacement 2 wheelers

- Uses hydraulic force on the basis of Pascal's Law to transmit force

- Only human effort is required to actuate the brake, no additional effort - electrical or any other type - is required

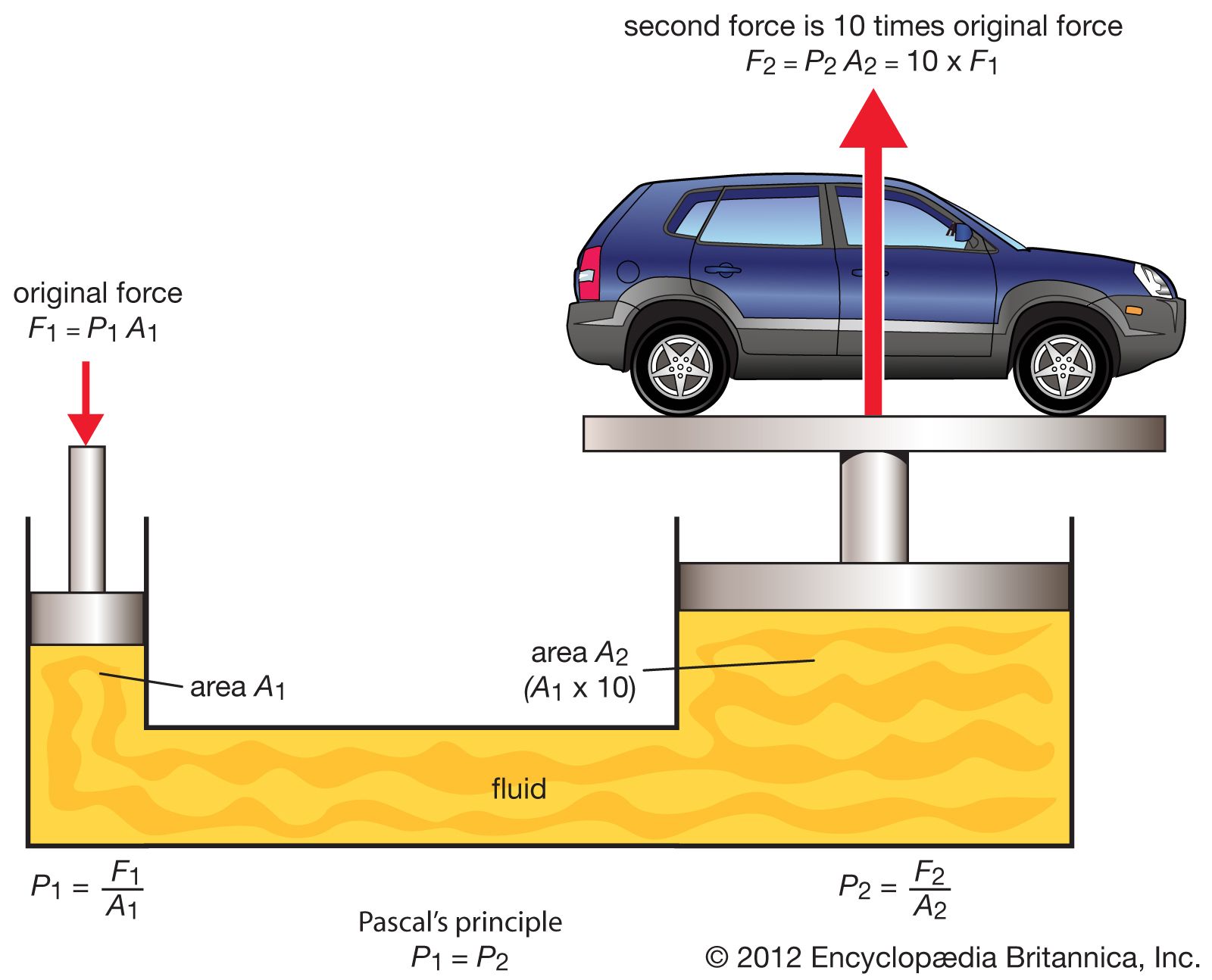

Pascals Law

- Pascal's Law, in simple terms, means that when you apply pressure to a incompressible fluid in a container/pipe, that pressure is transmitted equally throughout the fluid, in all directions.

- Since Pressure = (Force/Area), as area increases, force will increase proportionally to ensure same pressure is felt throughout.

=( ) & ,

When,

, which can be rearranged as,

that is, Force and Area will increase or decrease in direct proportion to one another

- In hydraulic brakes, this means the pressure from the brake pedal is transmitted through the fluid to the calipers at each wheel, causing the brake pads to cause friction against the braking surface to slow or stop the vehicle

- By using a larger piston area in the caliper (Near the brake pads) than in the master cylinder (near the driver input), the system can amplify the force applied by the driver.

3. Pneumatic

- Uses air as working fluid in this case.

- Since gases & liquids are both fluids, it will continue to obey Pascal's Law

- This system can offer the highest force multiplication as highly pressurized air is used

- Air at normal atmospheric pressure does not have the capacity to do meaningful work to push the pistons and cylinders, because it is still compressible, hence to make it incompressible to obey Pascal's Law, a compressor is used

- Compressor will compress air to a very high pressure and store in a pressurized air tank.

- Due to addition of compressor, additional load is placed on engine (in case of ICE), or on battery (in case of BEV)

- This will reduce the power output available at the wheel

- It will also add a lot of weight to the system

- Hence, it is usually used in vehicles like trucks or buses, or very large SUVs

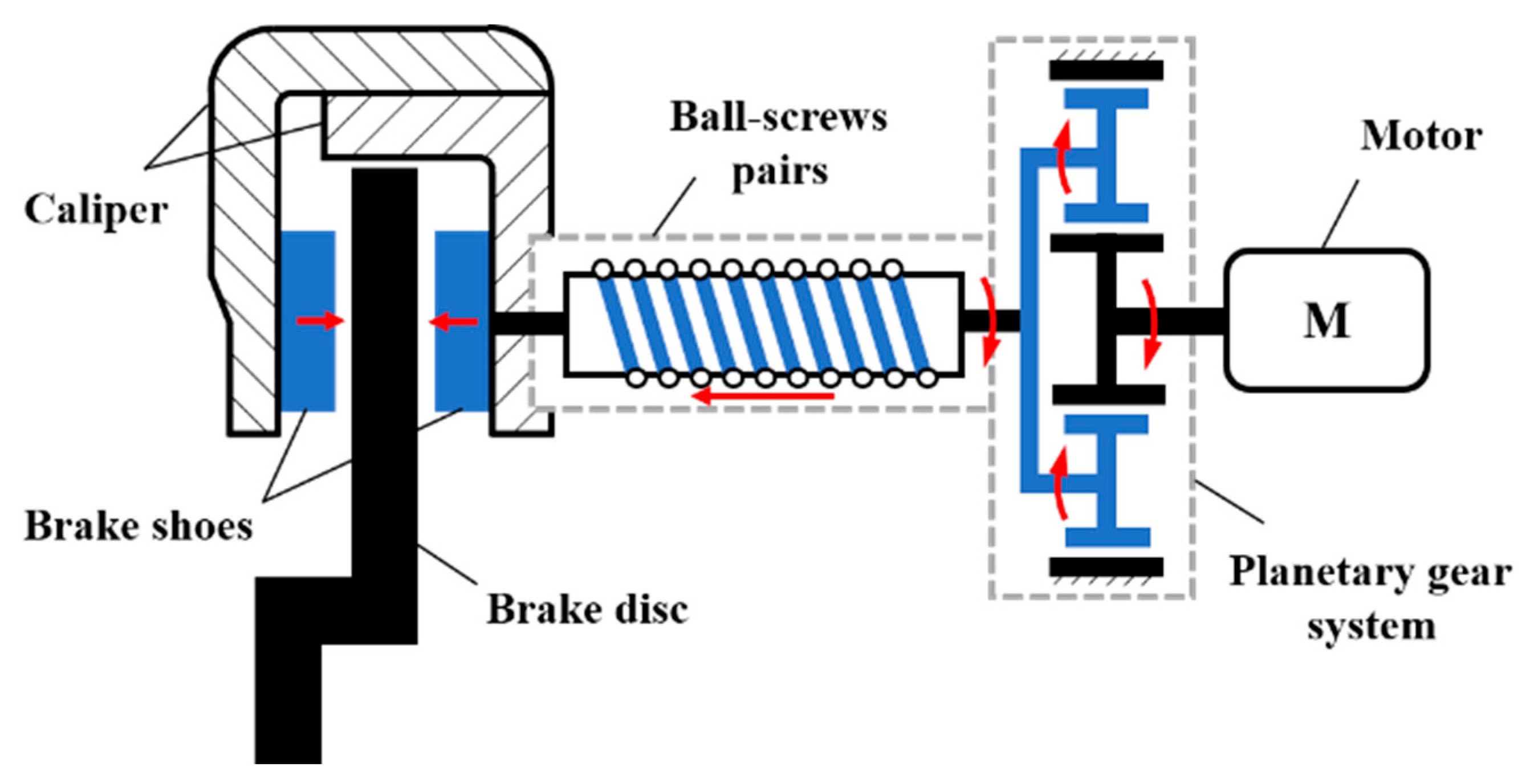

4. Electro Mechanical

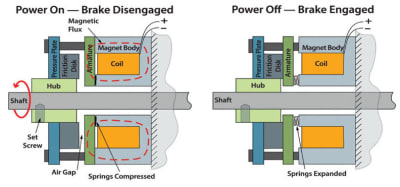

- Electromechanical brakes, also known as electromagnetic or EM brakes, use electromagnetic force to apply mechanical resistance and slow or stop motion.

An Example for motorized EM braking system

- They are a type of braking system that utilizes electrical and mechanical components, often employing an electric motor or actuator to apply the brakes, instead of relying on hydraulic or pneumatic pressure.

An Example for Electromagnetic EM braking system

- An electrical current flows through a coil on the brake, creating a magnetic field that moves an armature, engaging or disengaging mechanical components.

- This magnetic force then generates mechanical resistance or friction, slowing or stopping the vehicle

- Electromechanical brakes offer several advantages, including precise control for each wheel, shorter stopping distances, reduced brake drag, and potential for improved fuel efficiency or EV range.

- They can be used to actuate ABS Brake systems

- They also enable "brake-by-wire" systems, which can support autonomous driving

Classification based on Braking Surface

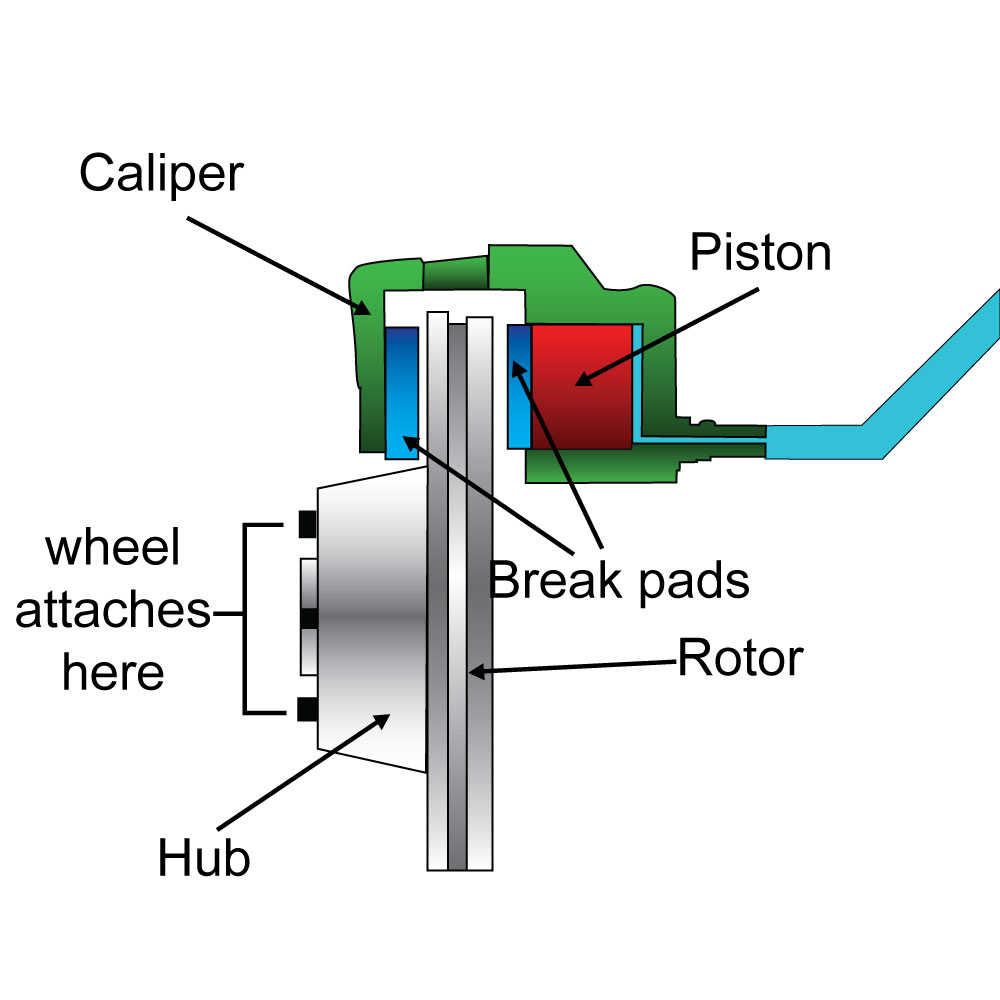

Disc Brake

- In a disc brake, braking force is applied on one or both surfaces opposite to the axial plane

Disc brake Constructional details

- It consists of a disc plate mounted on the wheel, which gives it the name - Disc Brake

- A caliper consisting of the brake pads is mounted around it

- In case of a hydraulic disc brake, piston is present in the caliper, which will push on the brake pads once brake lever is engaged, working based on Pascal's Law in hydraulic brakes

- The actuator pushes the brake pads closer to the disc plate causing friction, which reduces the rotational speed and eventually brings the vehicle wheels to a stop

- Holes are drilled and segments cut away from the disc plate to increase surface area for cooling brakes

https://www.youtube.com/watch?v=hD2z1P5qMUY

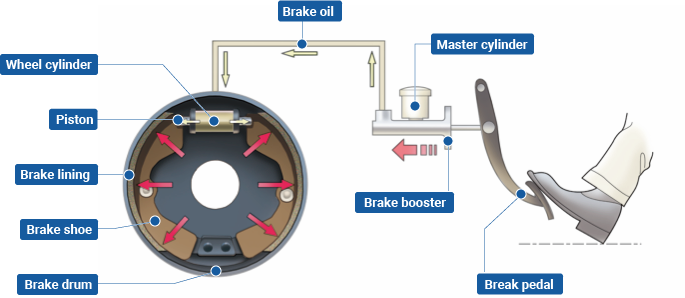

Drum Brake

- Here, the braking force acts along the radial surface of the drum

Drum Brake constructional details

- On applying brake force, the actuator will push the top edge of the brake liner away

- This will cause them to move closer and eventually in contact with the brake drum

- This will cause it to slow down and stop wheel rotation

- Once brake force is released, the spring will pull the 2 brake liners closer to each other and back to their original position

- We normally use this design where brake shoes are present inside the drum and expand outward, hence they are called Internally Expanding Drum Brakes

https://www.youtube.com/watch?v=ApuBEn2zct8&pp=0gcJCYYJAYcqIYzv

Brake Overheating

- On overheating the brakes, you might have reduced and erratic brake performance

- Common causes are poor & aggressive driving habits with rapid and extreme brake actuation, worn brake pads or improper brake installation

- You can identify it usually when a smoky smell is noticed, squealing noises, soft or spongy brake actuation and sudden reduction in braking distance & force

- Overloading can also cause brakes to overheat as a lot of inertia has too be overcome to brake the vehicle

- On overheating, the brakes could bind and stick with the brake pad causing the wheel to lock up and not release once driver disengages brake pedal

- The braking surface could also undergo a phenomena called Glazing

- Here the brake pads' surface and the braking drum's or disc's surface will change its properties

- Due to the rapid heating & cooling of these surfaces, they will form a hard, smooth and shiny shell which is very tough

- This will reduce the amount of friction available

- Since both brake pad and brakes now have tough surfaces, both will try to wear out the material on each other, ideally the pads are made softer so that we only have to periodically replace only the brake pads

- If glazing occurs, both brake pad and brake's friction surfaces will need frequent replacement

- One could use an abrasive like a grinding plate or sandpaper to slowly wear away surfaces to remove the glazing

- This can occur in disc and drum brakes and their brake pads

ABS System

- An Anti-lock Braking System (ABS) is a safety feature that prevents a vehicle's wheels from locking up during braking, which can lead to skidding and loss of control.

- It works by using sensors, valves, and pumps to modulate brake pressure, ensuring the wheels remain rotating while braking

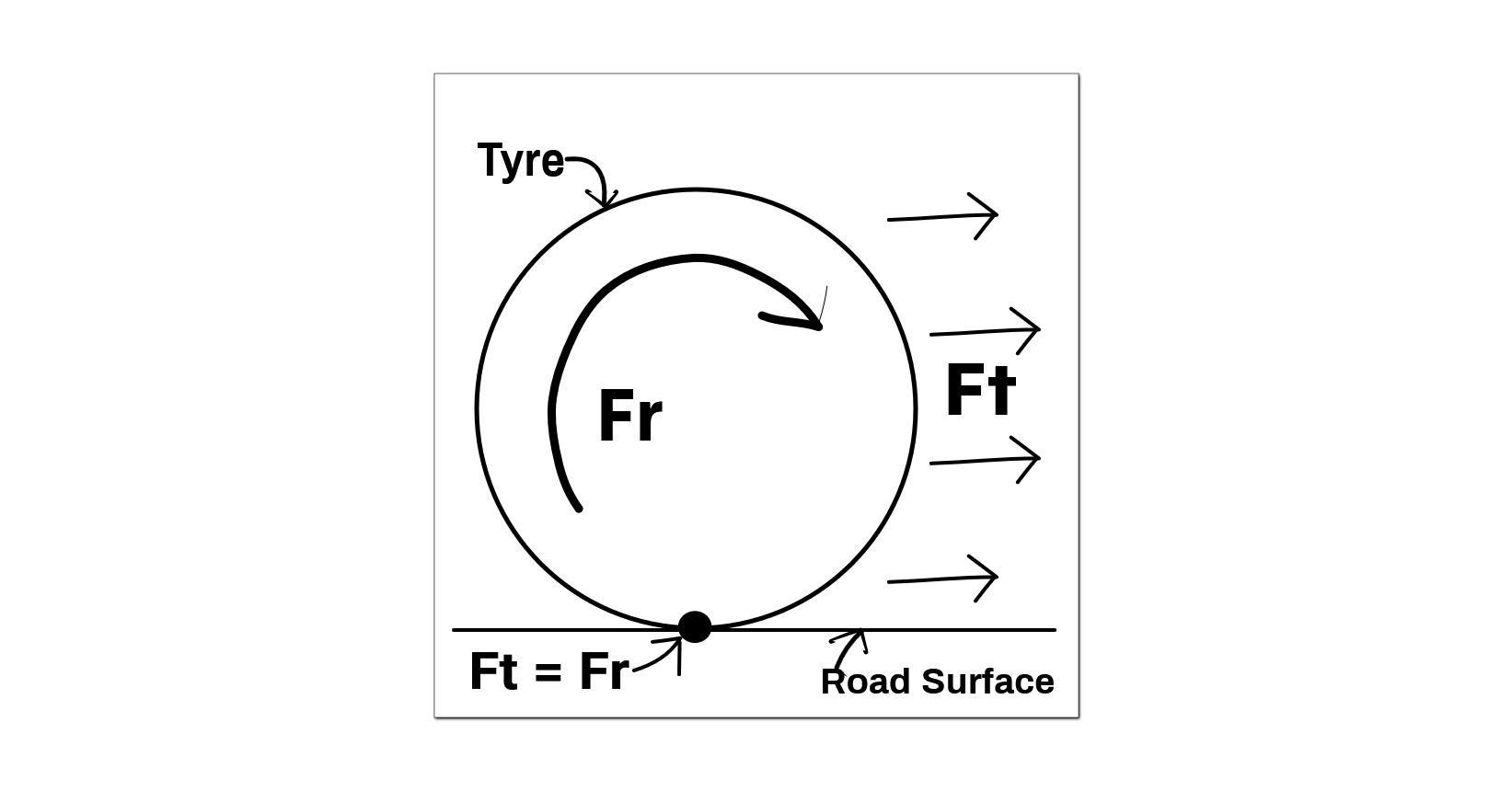

- In a wheel that is rotating on the road, 2 forces are interacting with each other to maintain grip along the road surfaces,

- The force causing the wheel to rotate is the Rotational Force (

) - The force causing the wheel to move forward is the Translational Force (

) - At the point of contact between wheel and tire, both these forces should be equal to ensure that wheel is in grip condition,

= - If the forces are not equal, one of 2 outcomes are possible

- If

> , wheel will rotate but not move forward in proportion, it will cause wheel to slip and rotate in the same place, it is called Wheelspin - When

< , the force pushing the wheel forward will cause the wheel to slip and skid in the direction of while the rotation will be slower or zero in comparison - In both cases, driver will lose control as the vehicle will not perform under braking as driver expects to.

- Vehicle will neither slow down or steer as intended

- We have this problem at speeds higher than 40 km/h

- The ABS system will work here to ensure that

= all the time - If it detects that

happens to be more than , it will release the brakes to give an opportunity to the wheels to increase rotational sped, such that = - It will re-engage the brakes once

= , and keep checking if there is any change in the condition - The moment

increases again, it will release the brakes again - This will keep repeating till driver disengages the brake pedal or if vehicle has come to a a standstill

- At lower speeds, vehicles don't tend to lose grip & hence ABS is ineffective here in aiding your braking performance

https://www.youtube.com/watch?v=98DXe3uKwfc

Reflective Question

Which vehicle would brake faster, an ABS or non-ABS, when brakes are applied in similar conditions?

Electronic Brake Distribution (EBD) System

- Present in cars or vehicles with 4W or more

- Works as an extension of ABS in 4W+ vehicles

- Electronic Brake Distribution (EBD) is a safety system that ensures the correct amount of braking force is applied to each wheel, especially when braking in different conditions.

- It is possible that while driving one or more wheels could lose traction, due to changes in surface of the road or due to presence of materials such as ice, snow, oil, sand, etc.

- This will cause the vehicle to yaw (slide in a circular fashion) and go into a uncontrolled spin

Yaw Motion

- Since driver control is lost, EBD will try to rectify it

- It works by analyzing the load on each wheel and adjusting the brake pressure accordingly on each individual wheel

- It prevents wheel lock-up and improves vehicle control, particularly during emergency braking or when cornering

- It will try to keep the vehicle in the same directional motion as the driver steers it

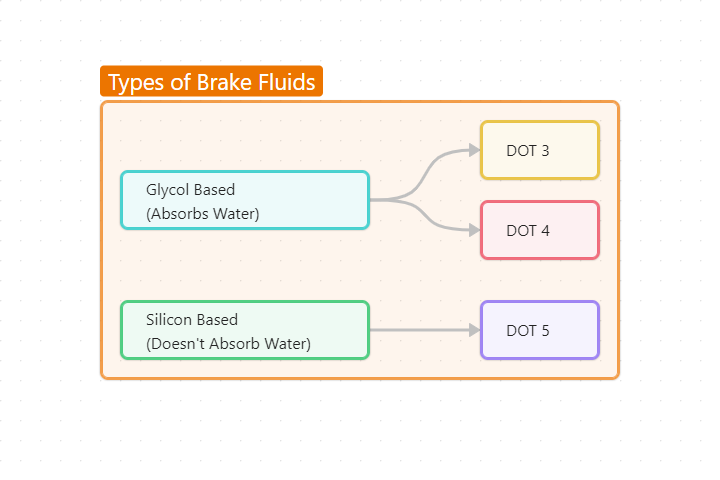

Brake Oils

- One of the important characteristics of brake fluid is its BOILING POINT.

- Hydraulic systems rely on incompressible fluid to transmit force.

- Liquids are generally incompressible while gases are compressible.

- If the break fluid boils (becomes a gas), it will loose most of its ability to transmit force.

- This may partially or completely disable the brakes.

Precautions

- As a DOT 3 or DOT 4 brake fluid absorbs water, its boiling point decreases.

- It can absorb water from air, that is why we should avoid opening the car’s brake fluid reservoir and the container of the brake fluid should be tightly sealed.

- Also DOT 3 and DOT 4 brake fluids eat paint.

- None of the different types of brake fluids should be mixed. They can react badly with each other and corrode the brake system.